Three Types of Slip for Pottery and Ceramics

In the post, I will show three different types of slips which are clay slips, engobes and casting slip. Slips and engobes are more or less the same thing. Slips are predominately liquefied clay and are usually applied on wet to dry greenware. Engobes usually have a lower clay content and can also be used on bisque fired ware. The word slip generally is used to describe any clay in liquid form. All slips and engobes can be coloured with oxides, stains and carbonates.

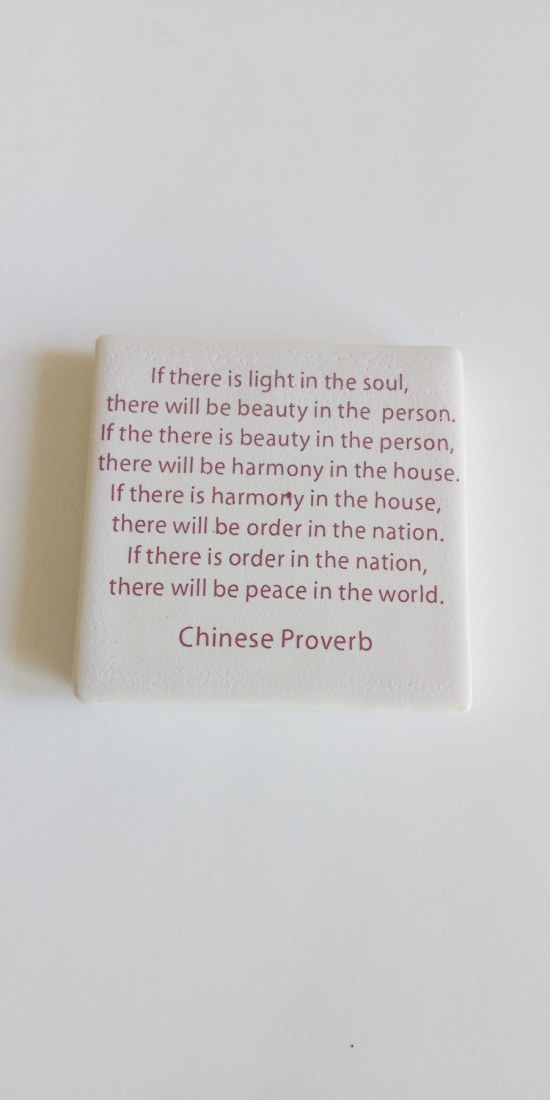

Beaver tumbler – blue slip on the outside, a clear glaze overall and then the addition of the waterslide decal

To produce slips for casting into plaster molds, the ingredients for slips are mixed with water to which 1% to 2% of a deflocculant such as sodium carbonate (soda ash) and/or sodium silicate has been added. Slips made with deflocculant require much less water to achieve the same degree of fluidity as those without deflocculant. The definition of a deflocculant is ceramics are materials that you add to your slips to make them smoother, flow a little better, and even apply a little better.

Pouring casting slip into a plaster mold

Casting slips give extremely good properties for use as a drawing medium in a fine to medium aperture trailer. Since there is much less water in the deflocculated slip, it will leave a crisp, raised line drawing when applied to a leather hard surface. To remove sharp points or develop a low relief , raised slip line drawings can be flattened with a rubber coated roller or print maker’s brayer.

Slips used for decorating are usually mixed with water only unless specific qualities of fluidity or viscosity are desired. For these qualities, a flocculant such as vinegar or Epsom salts can be used for increasing the viscosity or thickening. Decorating slips are usually used to coat the surface of clays in a variety of ways. They can be made from naturally occuring clays or from mixed materials and colourants to provide a range of decorative effects. They can be applied to wet, leather hard or dry clay bodies depending on the technique used the dry strength of the clay body. The slip decoration usually is covered with a glaze after bisque firing although some people prefer to leave the slip patterns unglazed.