Cuttle Fish Casting

Ok. I admit it. I have been missing in action and have been neglecting this blog. Everything is coming towards completion now that the year end is not so far away. In a few short weeks, I will have completed my jewellery casting class at Georgian College in Barrie, Ontario and it really has given my a whole new perspective on jewellery making.

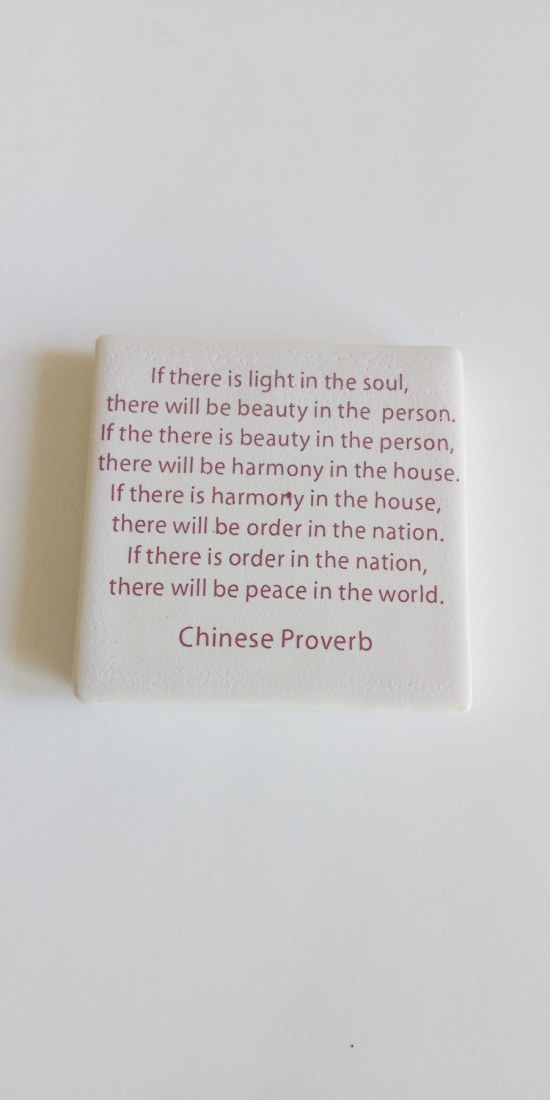

I made one piece through the cuttle fish casting method and in the time that I have left, I would really like to try my hand at making another piece. Here is a piece that I completed a few weeks back.

The jewellery making process is no less labour intensive than the ceramic process. I think it took me a while to figure out if I liked it because it is so opposite to working with clay which is so soft and malleable and it isn’t until it is fired that it becomes hard. With metal, you can always metal is back down if you really don’t like it and with clay you can reclaim it if it still in a raw unfired state. I would eventually like to work towards combining the two mediums.

Here is a bit more information about the cuttlefish casting process as most people that I have shown this piece to are quite intriqued by how it works.

Cuttlefish is a Mollusk making it cousin to the Squid. When the Cuttlefish dies its “bone” or more accurate internal shell washes up on beaches all over the world.

The cuttlefish “Bone” is very familiar to many people with budgies (budgies use it to sharpen their beaks), but for goldsmiths it is an excellent tool for casting.

Since the bone is soft (it can be scratched with a fingernail) it can be carved into with various tools to create a mold to cast molten metal into.

The bone itself also has a very distinctive “waive” texture and each bone is unique in its pattern. With great care the texture can be preserved and used as a design element in the cast piece of Sterling Silver jewellery.